Articles

- Aluminum alloy forgings: advantages and disadvantages

2022-09-01

As with any metal and alloy forming process, aluminum alloy forgings have advantages and disadvantages. Generally, aluminum alloys are forged with heat, but it can also be done in what is considered a cold process, where the alloy is not heated until the force is applied.There are several processes Read More - Choose the best forging manufacturers and suppliers

2022-09-01

There are many different considerations when choosing any type of service provider for an OEM. Unfortunately, choosing manufacturers and suppliers on pricing is often a mistake new OEMs make, leading to major issues with component quality, defects, waste, and potential challenges to project delivery Read More - Aluminium Alloy Use In Marine Industry

2022-09-01

Aerospace Marine Grade Aluminum Alloy Grades 5052, 5083, 5086, 6061, 6063, 6082, 6351 Global Supplier and Exporter.These Marine aluminium alloys(rolled and extruded) that are used in marine applications belong for the most part to two Series the 5000 (5083, 5086, 5754) series comprising aluminium-ma Read More - Processes used in aluminum forging

2022-08-19

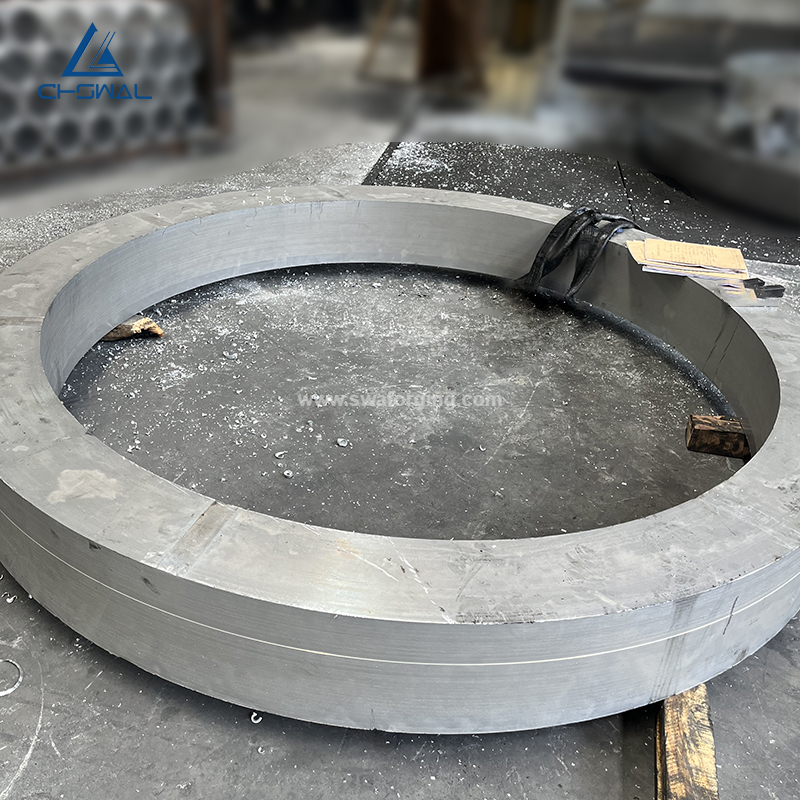

Aluminum is one of the most used materials in the world, and aluminum components are found in all walks of life. This includes aerospace components and parts for construction, process equipment, as well as electrical components and automotive manufacturing.There are several different ways to mold pa Read More - Aluminium Alloy Use In The Automotive Industry

2022-08-18

Leader supplier of aluminum automotive alloy grades such as 1100,5052,5083,6061,6082 etc.The car is the most common type of transport in the world which has most of aluminium alloy usage . These same properties of aluminium mean various alloys are now also used in passenger and freight rail cars, co Read More - Aluminium Alloy Use In The Aerospace Defense

2022-08-17

The aircraft and aerospace industries have long relied upon aluminum alloys. After the aluminum (aluminum-copper) alloys, the most important aircraft material in the future will be aluminum-lithium alloys. With aluminum-lithium alloys, it is possible to reduce planes by 15%.The importance and usage Read More - What are the advantages of aluminum alloys used in the automotive field?

2022-08-05

In recent years, aluminum alloys have been widely used in the automotive field. With the vigorous promotion and application of sustainable development strategies, automotive lightweighting has become the trend of automotive progress. In the process of lightweighting of automobiles, aluminum alloy ma Read More - How about the performance of forged aluminum 7075

2022-08-05

How about the performance of forged aluminum 70757075 forged aluminum plate is a cold-treated forged alloy with high strength and hardness, far superior to mild steel. 7075 aluminum plate is one of the strongest commercial alloys, with ordinary corrosion resistance, good mechanical properties and an Read More - Is the heat treatment process of large forgings complicated?

2022-07-28

Usually, the heat treatment of large forgings is combined with the cooling of forgings, due to the large section size and complex production process of large forgings. During the heat treatment process, some forgings are prone to white spot defects due to the uneven structure and properties of the f Read More - How to improve the quality of gear forgings

2022-07-26

In addition to the hardness value required to improve the quality of gear forgings, other mechanical performance indicators must also be specified:1. Reasonable combination of strength and toughness. Usually the strength and toughness of steel materials are trade-offs. For structural forgings, the p Read More - What is the processing flow of cake forgings?

2022-07-20

Cake satin parts are also called short shaft forgings. The processing process is divided into three types according to the difficulty of forming: ordinary forgings, high-hub deep-hole forgings and high-rib thin-walled complex forgings. The processing process is generally upsetting. , Upsetting to ga Read More - What should be paid attention to in the forging process of heavy forgings

2022-07-20

A heavy forging is when a large piece of metal is stressed and shaped to serve its purpose. This force is typically achieved through the use of a hammer or pressure. The forging process builds a refined grain structure and improves the physical properties of the metal. In real-world use of the compo Read More